3DBioFibR: Collagen Fibers for in-vitro Tissue Engineering

.webp)

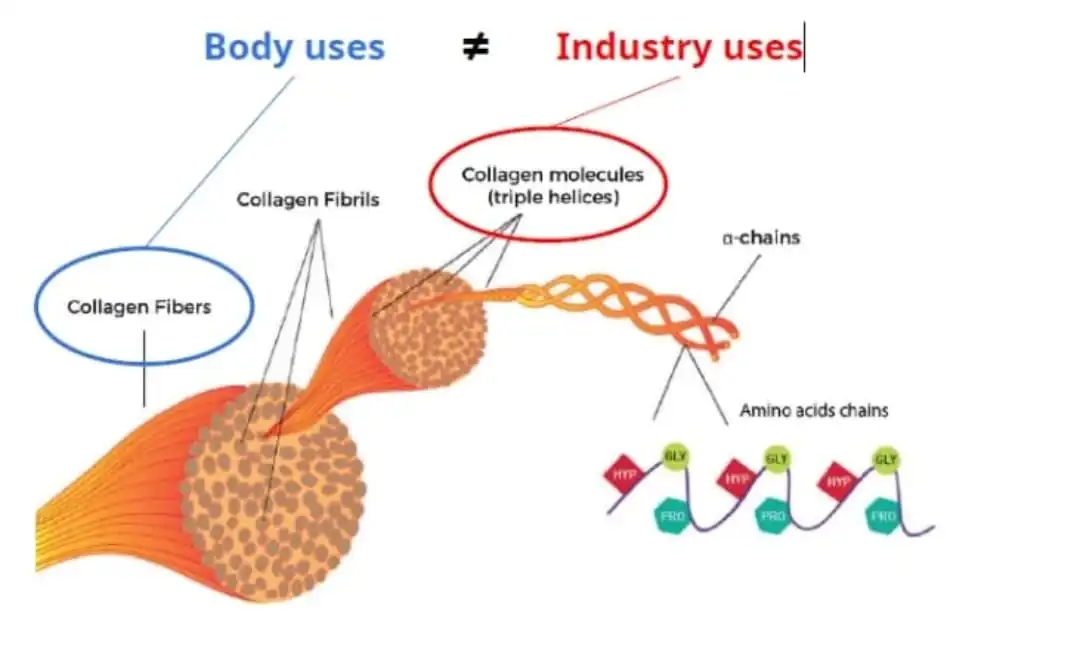

3DBioFibR’s patented and fully automated dry-spinning technology enables production of CollaFibR™: collagen fibers that closely recapitulate the biomechanical and biochemical properties of natural collagen fibers.

CollaFibR™ is made using GMP bovine skin collagen. The collagen is combined with a scaffolding polymer in 20 mM acetic acid, from which the fibers are spun. The spinning process drives the alignment of the collagen within the fiber, driving self- assembly.

Once these fibers are subsequently hydrated in aqueous environments, the scaffolding polymer is fully removed resulting in a pure collagen fiber scaffold.

Tailoring porosity, fiber alignment, and density, 3DBioFibR has the ability to create customizable scaffolds for diverse end-user applications!

Click here to view the video on 3DBioFibR Automated Manufacturing Platform.

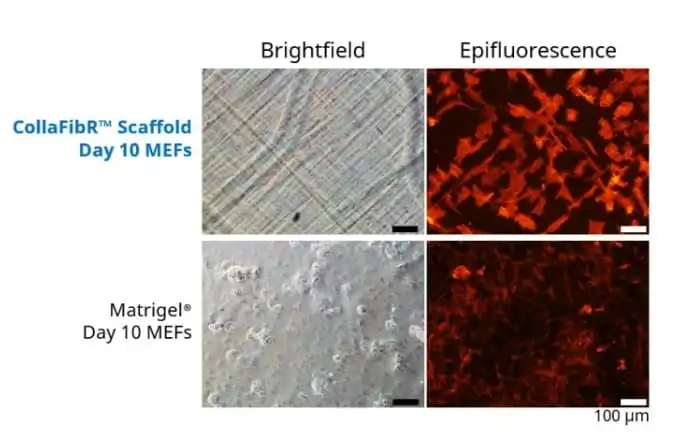

CollaFibR™ Scaffold for Cell Culture

CollaFibR™ scaffolds offer a well-defined composition, are easy to use, and can be stored at room temperature. Just like transwell, except with collagen fibers! CollaFibR™ also offers superior epifluorescence imaging, minimizing background interference for precise analytical capabilities.

μCollaFibR™ Additive for Bioinks and Hydrogels

It’s a challenge to create a bioprinted construct that retains it’s shape and is physiologically relevant. μCollaFibR™, an additive for hydrogels and bioinks that is revolutionizing the 3D Bioprinting industry provides the solution for this.

Made up of short collagen fibers, with an average length of 50 μm and 1-2 μm diameters, this additive prevents uncontrolled contraction of bioprinted constructs, leading to improved shape retention!